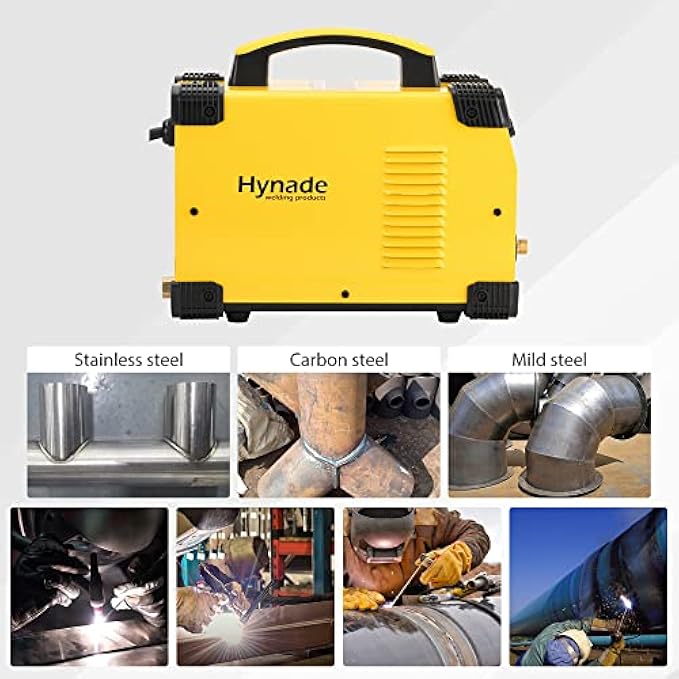

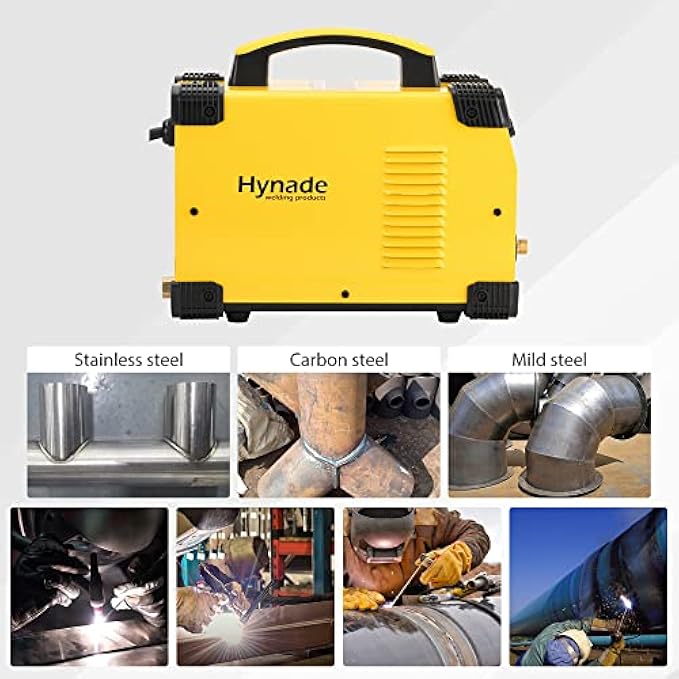

hynade Tig Welder TIG215A, HF ARC/TIG/Stick TIG Welders 215 Amp 110/220V Dual Voltage TIG Welding Machine

Inhouse product

-

CMI Corporation Rope Jack

$319.00

-

introduction

04-04-2023I have literally no idea what I'm doing when it comes to TIG but I watched a few videos and went for it. This box has absolutely no problem working with mild and stainless, and it's got enough flexibility with the settings to work with most setups. I'm currently running it off 110v and have had no issues with thinner mild steel. My only suggestion for improvement would be an increased post-flow time, as it currently maxes out at 6 seconds.

-

KoolTy

04-04-2023I have literally no idea what I'm doing when it comes to TIG but I watched a few videos and went for it. This box has absolutely no problem working with mild and stainless, and it's got enough flexibility with the settings to work with most setups. I'm currently running it off 110v and have had no issues with thinner mild steel. My only suggestion for improvement would be an increased post-flow time, as it currently maxes out at 6 seconds.

-

Wotifra

05-04-2023This appears to be a cheap knock-off of the more expensive Leister model. As others have noted, the temperature control is very fussy. It makes an rapid transition from cold to full heat in a small fraction of a turn. (If you're handy, this can be partly resolved by replacing the 330K potentiometer with a 100K pot, or just put a 100k resistor across the two leads. Another option is to keep it connected to a watt meter so you can make the necessary fine adjustments.) Next problem: The maximum wattage in only about half of the 1600 watts claimed, so it may not get hot enough for some plastics. Again, this seems to be a problem with the control circuitry. The heating element does draw about 1500 watts at 120V, but the SCR control circuit only gets it up to about 700 watts. OK for some jobs, but not enough for others. If you can live with these limitations, go for it. Otherwise be prepared to spend a lot more for one of the original tools.